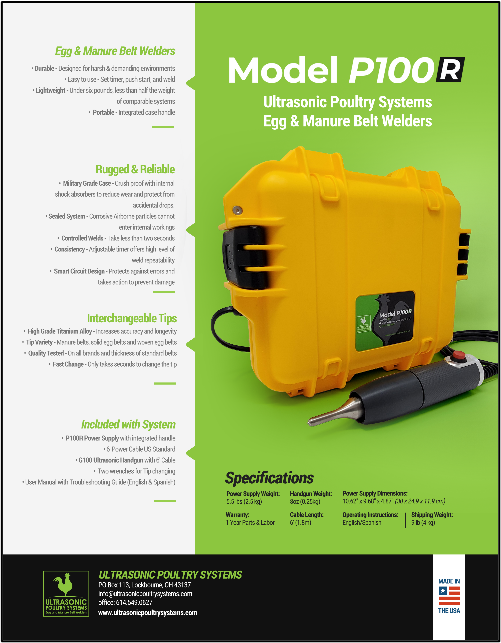

The new P100R Ultrasonic Welder is built for mobility, operates in harsh and dusty environments, and features a rugged crush proof case for safe and easy portability…

For Release: June 1, 2021 - Grove City OH

When Ultrasonic Poultry Systems (UPSS) developed its first product four years ago, the P100 Ultrasonic Welder, which was engineered to specifically serve the poultry industry and to address the deficiencies seen by other products in the market. Then late last year UPSS rolled out the next generation P100R Ultrasonic Welder, and the initial feedback from early adopters has been widely acclaimed.

“We looked at where and how these devices are being used, and then designed the P100R for the ruggedness and simplicity needed to meet the industry’s requirements”, says UPSS founder and CEO Alex Spurgeon. “Based on years of feedback and close work with end users, the P100R now offers new key features that have proven to excel at operation and performance.”

The new upgraded P100R was tested rigorously on a wide variety of manure and egg belts to verify both reliability and effectiveness.

These improvements reduce down time, which is critical to the industry.

Designed for harsh environments of a poultry barn, easy to use and versatile for use on both egg and manure belts, the new features in the P100R include:

• A 0-10 second timer for consistent and reliable welds - The timer makes it easy for new users to set the timer and always weld to a consistent depth creating a reliable and consistent maintenance process

• Built-in power supply making the unit extremely portable and easy to maneuver - users can easily move around the facilities with the device and get to their work area and perform the needed maintenance

• A new H6 titanium welding tip that allows for faster welding with increased strength, a truly superb improvement in the industry – it revolutionizes the process significantly speeding up the welding process and creating a stronger more durable weld to reduce weak points and future failures.

Additional Standard Features:

- Rugged, reliable, and dust proof design ensures long lasting use with protection from corrosive airborne particulates

- Impact resistant components contained in a crushproof case

- No complicated keypad – only a timer knob and a start button

- Able to run on 110VAC/220VAC

- Weighs only six pounds making the P100R versatile and portable

- Interchangeable Titanium Tips provide the ability to weld both egg and manure belts with one system

- Controlled Welds which typically takes less than 3 seconds

- Warranty - one-year parts & labor

More About Ultrasonic Poultry Systems

Ultrasonic Poultry Systems in known for innovative and heavy-duty ultrasonic belt welding systems and offers sales, service, and support to USA, Mexico, South America, and Canada.

Proudly made in the USA

Reach Us

Ultrasonic Poultry Systems LLC

3971 Hoover Rd #291

Grove City, OH 43123

614.549.0627